Danfoss co-operation

In February 2020, Danfoss set an ambitious goal to achieve carbon neutrality in all of its global operations by 2030. This goal is based on scientific calculations and is now more relevant than ever. We are proud and grateful to support Danfoss’ progress in collaboration with LUT University through various product development projects. In this customer story, we share how 3D scanning was utilized for quality assurance as part of the test system we delivered.

3D Scanning in Quality Control

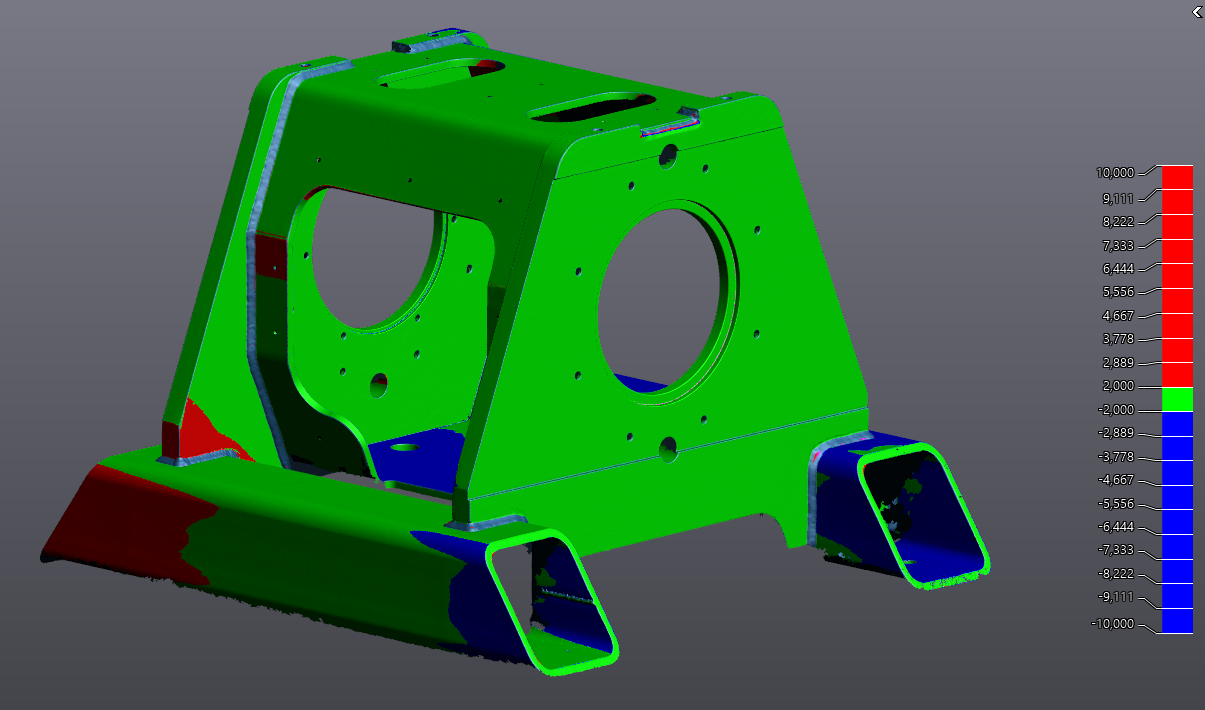

One of the most effective ways to illustrate deviations from the nominal 3D model is color map comparison. The scanned mesh model is aligned with the nominal CAD model, allowing deviations to be presented not only as precise numerical values but also as a visually intuitive color map. This method enables accurate quality assurance and simplifies the interpretation of deviations.

Test System Delivery and Analysis

As part of the project, we designed and delivered a test bench along with the necessary auxiliary components. After that, we performed a 3D scan of the test bench and analyzed the collected data using the VX Inspect quality assurance software. Verifying geometric tolerances can be challenging with traditional methods, but with 3D scanning and advanced software, we can conduct a precise conformity analysis and generate an easily interpretable, visual report.

Color Map Comparison – The Key to Clear Analysis

The color map can be customized to highlight areas exceeding or falling below a specified threshold with different colors. For example, in the color map, deviations greater than 2 mm are displayed in blue or red, depending on the direction of the surface deviation. Deviations within the set threshold are shown in green, making the overall picture easy to interpret at a glance.

This modern 3D scanning-based quality assurance method helps ensure that product development and manufacturing remain high-quality and efficient. The collaboration with Danfoss and LUT University demonstrates how, as technology advances, quality assurance methods can also make significant strides forward.