Power Electronics Laboratory

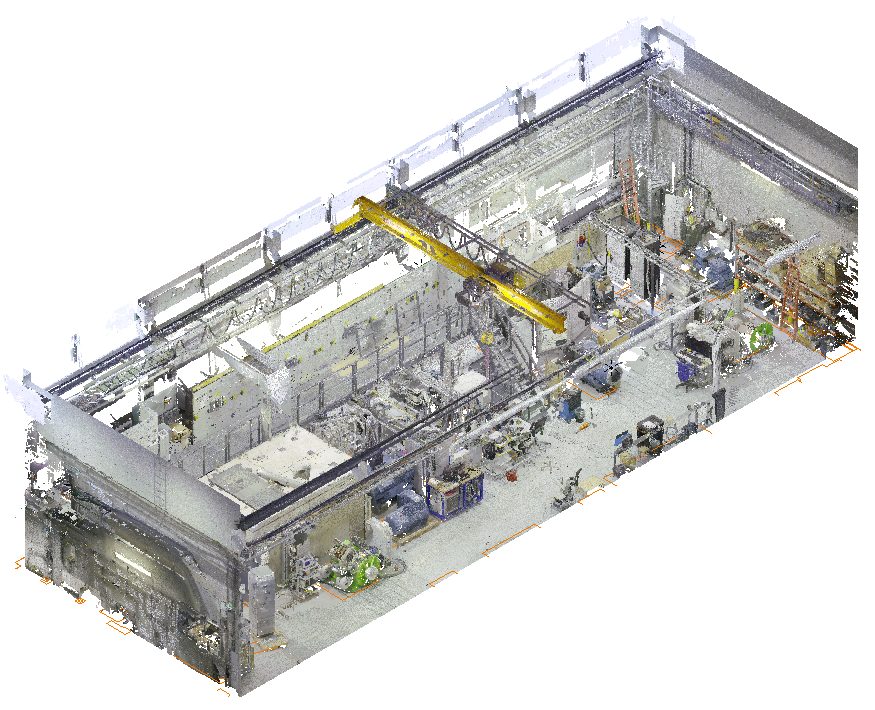

Laser scanning of a LUT University power electronics laboratory. The space is approximately 270 m2 in size and it was made into a Basic level As-Built model.

Nuclear Engineering Laboratory

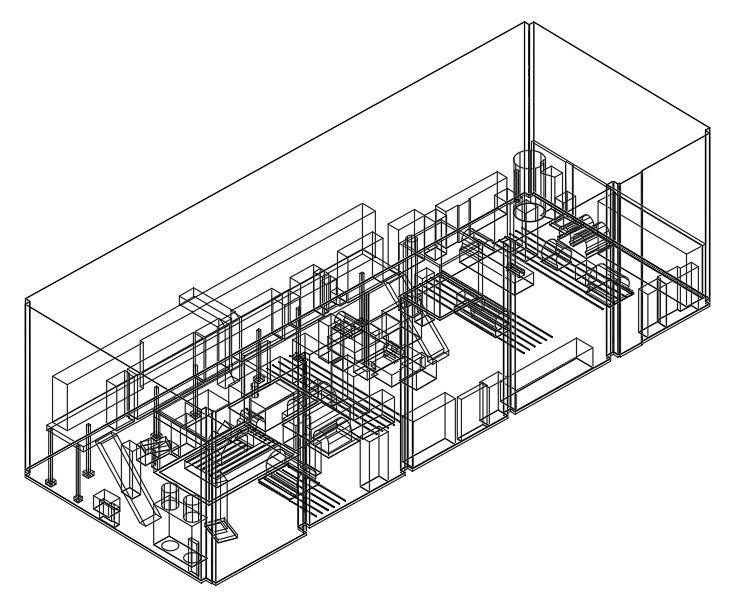

Laser scanning of a LUT University engineering power laboratory. The space is approximately 500 m2 in size and it was made into an Advanced level As-Built model.

Power Electronics Laboratory

At Lappeenranta University of Technology, the Power Electronics Laboratory is developing high-speed technology to achieve a leading position as a developer of new techniques in the energy transition. The laboratory houses numerous electric motors, control centers, and measuring devices that have been acquired and installed over the years. In the initial situation, the space lacked an up-to-date layout, and as additional acquisitions were planned, the room was becoming crowded. The decision was made to acquire an up-to-date 3D layout through laser scanning.

The Power Electronics Laboratory is approximately 270 m2 in size and has a hall-like space that is 8 meters high. The space was laser scanned from 24 different measurement points. Laser scanning the laboratory took about half a workday, and the second half of the workday was spent creating the 3D model. This is also known as registration. The point cloud model was ready in a day.

The point cloud model can be used with software such as SolidWorks, Inventor, AutoCAD, ReCap, or NavisWorks. However, there is no need for paid software since the model can be opened and measurements can also be taken using free software such as NavisWorks Freedom. In addition to the 3D model, a 360° photograph is taken from each scanning point. Other 3D models can also be imported into the point cloud model, which can be used, for instance, to verify feasibility of installing new machinery or the compatibility of pipeline modifications with the space.

The laboratory was also modeled into a solid 3D CAD model using Autodesk Inventor. The point cloud model served as the basis, and a rough Basic level 3D CAD modeling was done on top of the model. The 3D CAD model was completed approximately in a day. From the 3D CAD model, a DWG file showing only the outlines was published, which is well suited for 2D layout planning, for example, with AutoCAD.

Nuclear Engineering Laboratory

The nuclear engineering laboratory consists of two different spaces, totaling approximately 500 m2 space. Based on the laser scanning data, a precise and visually detailed As-Built Advanced model of the space was created. For instance, the railings, pipes, and equipment are modeled very close to reality. The model also accurately replicates the color scheme of the space. Additionally, 3D models provided by equipment manufacturers have been incorporated into the layout. This resulted in a visually appealing outcome that can be utilized not only for space planning but also for presentation purposes. The laser scanning process took approximately one workday to complete.